Complete Steam Turbine Repair, Overhaul & Field Maintenance Services

OEM-Quality Steam Turbine Repair & Maintenance Services

At FOX Innovation & Technologies (FIT), we specialize in comprehensive steam turbine repair, overhaul, and field maintenance. From minor component replacement to major turbine rotor work, our highly trained technicians deliver solutions that enhance performance, reliability, and lifespan—without the OEM lead times or limitations.

With operations spanning North America, Europe, and South America, FOX brings global reach and deep turbine expertise to every project.

Start your steam turbine project with FOX

Steam Turbine Maintenance & Repair Services:

Our expert field teams and engineering support staff deliver high-quality steam turbine services across all major industries. From scheduled outages to 24/7 emergency repairs, FIT is the partner of choice for critical rotating equipment support.

Our comprehensive steam turbine service capabilities

Full turbine disassembly & inspection. Open-Clean- Inspect & Close (OCIC)

Rotor service, overhauls and balancing:

Rotor disassembly and cleaning

Detailed NDE (non-destructive examination) and dimensional inspections

Bore and journal repairs (in place or removed)

Low- and high-speed balancing

Blade replacement, welding, or machining

Rotating Seal Inspection and Refurbishment

In-shop dynamic balancing with QA certification

Valve and actuator inspections, repairs, and retrofits:

Detailed valve condition assessments

Blasting, NDE, Dimensional (Clearances /TEOT), Lapping/Contact Check, Reassembly with Stroke/Verification

Hydraulic and pneumatic actuator testing

Replacement of worn or malfunctioning valve internals

Inspection & Calibration of control valves and linkages

Upgrades to modern actuator systems for improved reliability (EHC)

Complete Engineering assessments with logistics and software interface controls and modules

Steam path and diaphragm alignment and inspections:

Upper and lower casing fit-up verification w Metrology Inspection

Diaphragm bore and hook fit inspections

Seal Strip, Caulking strip and stationary seal refurbishments

Diaphragm Sealing surface inspection w weld repairs

Nozzle segment condition evaluations and weld repairs

Blade tip and seal surface inspections

In-situ diaphragm machining and bolt hole repairs

Measurement and adjustment of clearances to optimize flow and efficiency

Rotor-train Alignment:

Comprehensive alignment of multi-machine train systems (e.g., turbine to turbine, gearbox, generator)

Hot and cold alignment analysis

Dynamic thermal growth and operating condition compensation

Laser-based shaft alignment and optical verification

Complete documentation and certification for regulatory and QA compliance

Vibration optimization & Troubleshooting

Shell/casing Thermodynamic growth analysis

Efficiency Evaluation with emphasis on Carbon Reduction

Casing, seal, and pedestal service/refurbishment, machining, & Alignment

Generator alignments, balancing & electrical testing:

In-place/robotic inspection of generator windings

Polarization index (PI) testing

Insulation resistance (IR) testing

Wedge tightness and end winding bracing inspections

Visual inspections and borescope evaluations

Hydrogen Seal Inspections, Replacements, and Service

Rotor and Stator Dry Ice Blasting

Complete Bearing Inspections:

NDE techniques, including dye penetrant, ultrasonic, and eddy current

Alignment and fit-up analysis of bearing housings

Shaft journal and bearing surface inspections

Precision measurement of clearances and tolerances – Analogue and 3D

Recommendations for re-babbitting or replacement

Post rotor alignment bearing alignment checks – Twist & Tilt

Bearing Design & Material Custom Upgrades

Lubrication System Inspections

Comprehensive inspection of lube oil skids and pump assemblies

Main Oil Pumps (MOP), Auxiliary Oil Pumps (AOP), and Emergency systems

High-Velocity Oil Flush (HVOF) for removing varnish and particulate buildup

ISO 4406 oil cleanliness sampling and compliance (17/15/12 or better)

Filter integrity checks and oil quality diagnostics

Piping and instrumentation review for leaks, restrictions, or improper routing

Support for commissioning, upgrades, and long-term maintenance plans

Metrology Services:

Precision onsite measurement using laser tracker-based systems

Troubleshooting of casing distortion, shell warping, and thermal growth behavior

Full-dimensional inspections of turbine components, diaphragms, and bearing pedestals

Steam path alignment analysis and casing-to-rotor fit-up verification

Support for outage planning, reverse engineering, and QA documentation

Steam Turbine Field Upgrades & Engineering Solutions

FOX engineers work with plant operators to identify performance improvement opportunities:

Reverse engineering of aging or obsolete parts

Custom coatings & wear surface upgrades

Efficiency tuning & revamp design

Steam path redesign consulting

Control system retrofits

We tailor upgrades to meet your performance and budget goals—improving output, reducing risk, and extending life.

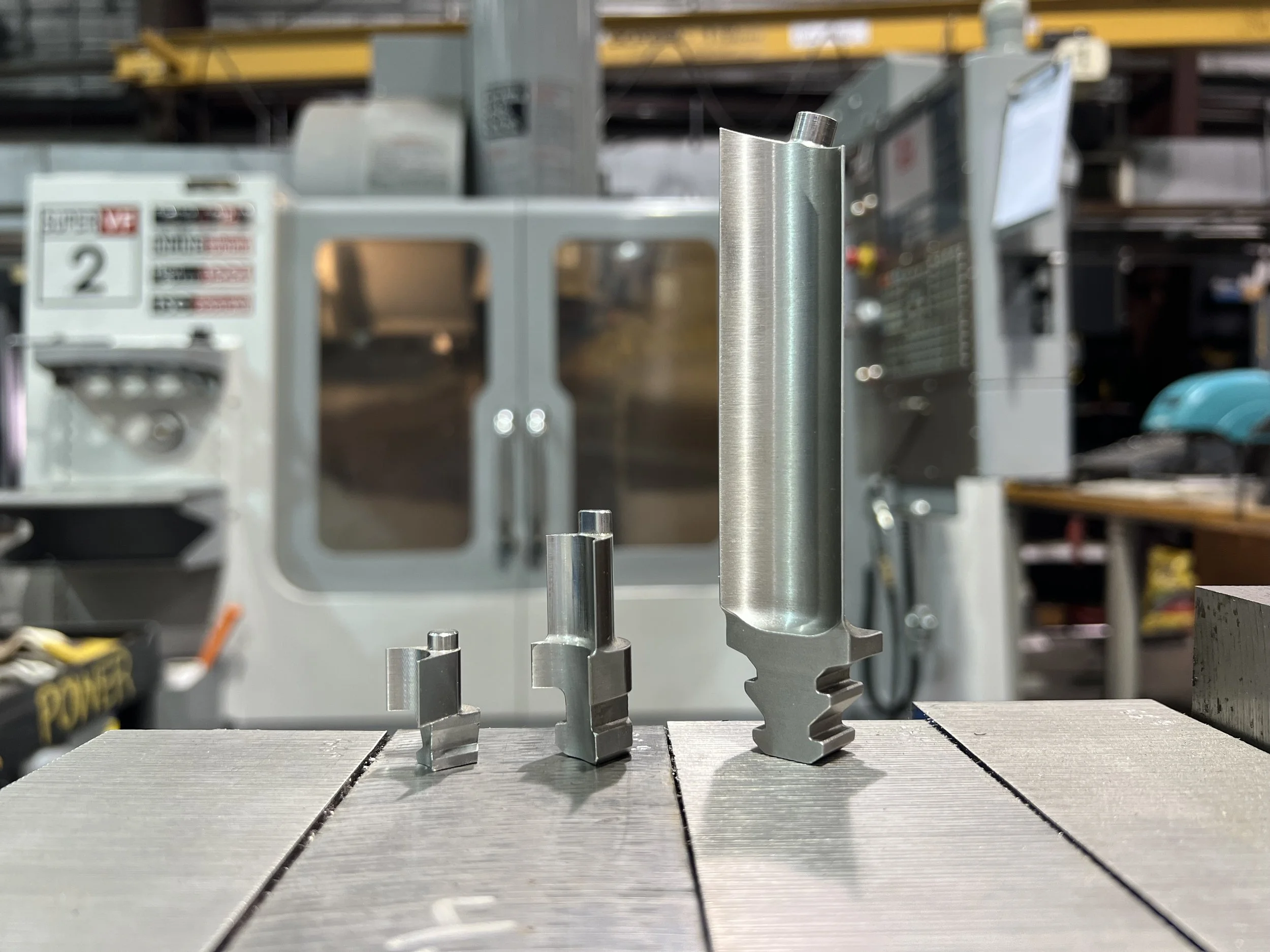

Steam Turbine Spare Parts & Reverse Engineering

From blade repair to complete rotor components, FIT offers:

Replacement and aftermarket turbine parts

Reverse engineering of discontinued components

Custom-designed seals, nozzles, and buckets

Replacement Packing

Bearings and precision hardware

All parts are manufactured to meet or exceed OEM standards, with inspection and QA documentation provided.

Why Choose FOX as a Trusted Partner for Steam Turbine Projects

Over 200 years of combined steam turbine expertise

Union-trained millwrights and certified foremen

Seamless coordination between field, machining, and engineering

In-house metrology, machining, and control system integration

FAQs

-

Yes. FOX Innovation & Technologies provides comprehensive repair, overhaul, and upgrade services for high-pressure (HP), intermediate-pressure (IP), and low-pressure (LP) steam turbine sections. Our capabilities include:

Rotor and diaphragm inspections for all turbine stages

Blade and bucket replacement or restoration (weld repair, coating, or re-blading)

Casing refurbishment and alignment correction

Seal system and gland steam repair or redesign

Nozzle, valve, and control system maintenance

By integrating mechanical, control, and performance engineering, FOX ensures each turbine stage is optimized for reliability, efficiency, and long-term operation.

-

Yes. FOX Innovation & Technologies provides turnkey balance-of-plant (BOP) support for a wide range of systems, including steam piping, condensers, feedwater heaters, valves, lubrication systems, and control instrumentation. Our holistic approach ensures complete plant reliability and seamless integration between the turbine and auxiliary systems.

-

Yes. Emergency response for condensing and non-condensing turbines is a top priority for FOX Innovation & Technologies. Our rapid mobilization teams and strategically positioned resources enable quick on-site intervention — from mechanical repair and weld restoration to alignment and startup validation. This responsiveness has made FOX a trusted partner for critical emergency support across various industries.

-

Yes. Critical-path outage execution is one of FOX’s core strengths. We can customize outage plans to meet your production deadlines — balancing safety, quality, and efficiency. Our teams manage field disassembly, inspection, repair, and recommissioning with precision coordination to minimize downtime and restore operations on schedule.

-

Yes. FOX Innovation & Technologies delivers precision alignment and dynamic balancing for steam turbine-generator sets. Using advanced laser and optical metrology systems, our specialists ensure accurate coupling geometry, reduced vibration, and extended bearing life. These procedures restore smooth, efficient performance for critical rotating assets, ensuring long-term reliability and energy efficiency.

Request a Quote

Have a steam turbine project or upcoming outage? Reach out today to discover how FOX Innovation & Technologies can become your trusted partner.