Steam Turbine -Industries and Applications

Do you have a steam turbine project we can help with?

At Fox Innovation & Technologies, we understand that steam turbines are at the heart of countless operations—from powering massive utility plants and driving mechanical equipment in refineries to supporting marine propulsion and renewable energy projects. Our team delivers OEM-quality repair, overhaul, and field services across industries including power generation, oil & gas, petrochemical, pulp & paper, and marine. Whether it’s precision rotor work, component upgrades, or outage support, we provide tailored solutions designed to maximize efficiency, reliability, and uptime for every turbine application.

Our steam turbine supervisors have extensive experience working with the top USA and European turbine equipment manufacturers.

Industries We Serve

-

Oil and Gas

-

Petrochemical & Refining

-

Power Generation

-

Nuclear

-

Process Plants

-

Pulp & Paper

-

Industrial Manufacturing

-

District Energy & CHP Plants

At Fox Innovation & Technologies, our expertise spans every turbine application, ensuring OEM-quality service, upgrades, and maintenance. Some of the steam turbines we service in the industry or operating environment include:

Marine Steam Turbines

Designed for ship propulsion (e.g., Navy ships, older ocean liners). Compact, rugged, often geared to propeller shafts.Mechanical Drive Steam Turbines

Used to power mechanical equipment such as compressors, pumps, or blowers. Often, back-pressure or non-condensing types are used to provide process steam.Industrial Process Steam Turbines

Found in refineries, petrochemical plants, pulp & paper mills, and sugar mills. Provide both shaft power and process steam (cogeneration).Utility Power Generation Turbines

Designed for large-scale electricity generation in power plants. Include condensing turbines for maximum power output.Cogeneration (CHP) Turbines

Combined Heat & Power units supplying electricity + useful heat/steam. Common in hospitals, universities, and industrial complexes.Geothermal Steam Turbines

Run on saturated or superheated steam directly from geothermal reservoirs. Typically designed for wet steam and mineral-laden conditions.Nuclear Steam Turbines

Powered by steam from nuclear reactor heat exchangers. Large, multi-stage condensing turbines optimized for high reliability.

Steam Turbine By Application Cycle:

Simple Cycle

Steam is used once in a single expansion through the turbine.

▸ Common in industrial use or standalone power plants.

Combined Cycle (with HRSG)

Steam turbine is part of a system recovering heat from a gas turbine via a Heat Recovery Steam Generator (HRSG).

▸ Very efficient; used widely in modern gas-fired power plants.Regenerative Cycles

Steam is extracted for feedwater heating to improve thermal efficiency.

▸ Common in utility plants and thermal optimization designs.Binary Cycle (Organic Rankine Cycle)

Uses lower-boiling fluids like isobutane or pentane to extract heat from geothermal or waste heat sources.

▸ Small-scale and renewable-focused.

As a leader among steam turbine repair service companies, we offer an array of steam turbine solutions, including innovative reverse engineering capabilities, spare parts packages, maintenance, and operational assistance.

Steam Turbine - Mechanical Configurations

Condensing Turbines

Steam expands and exits to a condenser under vacuum.

▸ Used in utility-scale power plants for maximum energy extraction.

Back-Pressure Turbines

Exhaust steam is used for industrial processes (e.g., heating, drying).

▸ Common in industrial cogeneration / combined heat & power (CHP) plants.Extraction Turbines

Steam is extracted at intermediate stages for process use or reheating.

▸ Can be controlled extraction (valved) or uncontrolled (bleed points).Reheat Turbines

Steam expands partially, is reheated in a boiler, then returned to the turbine.

▸ Increases thermal efficiency; common in large power plants.

Steam Turbine Maintenance & Repairs

With our global capabilities, we are able to provide you with effective and fast steam turbine maintenance and repair services. Our team brings over 200 years of combined experience to the table, giving us the expertise we need to deliver steam turbine solutions for a wide range of challenges. Our specialized technicians are able to leverage the necessary resources and knowledge we possess to deliver the results you need.

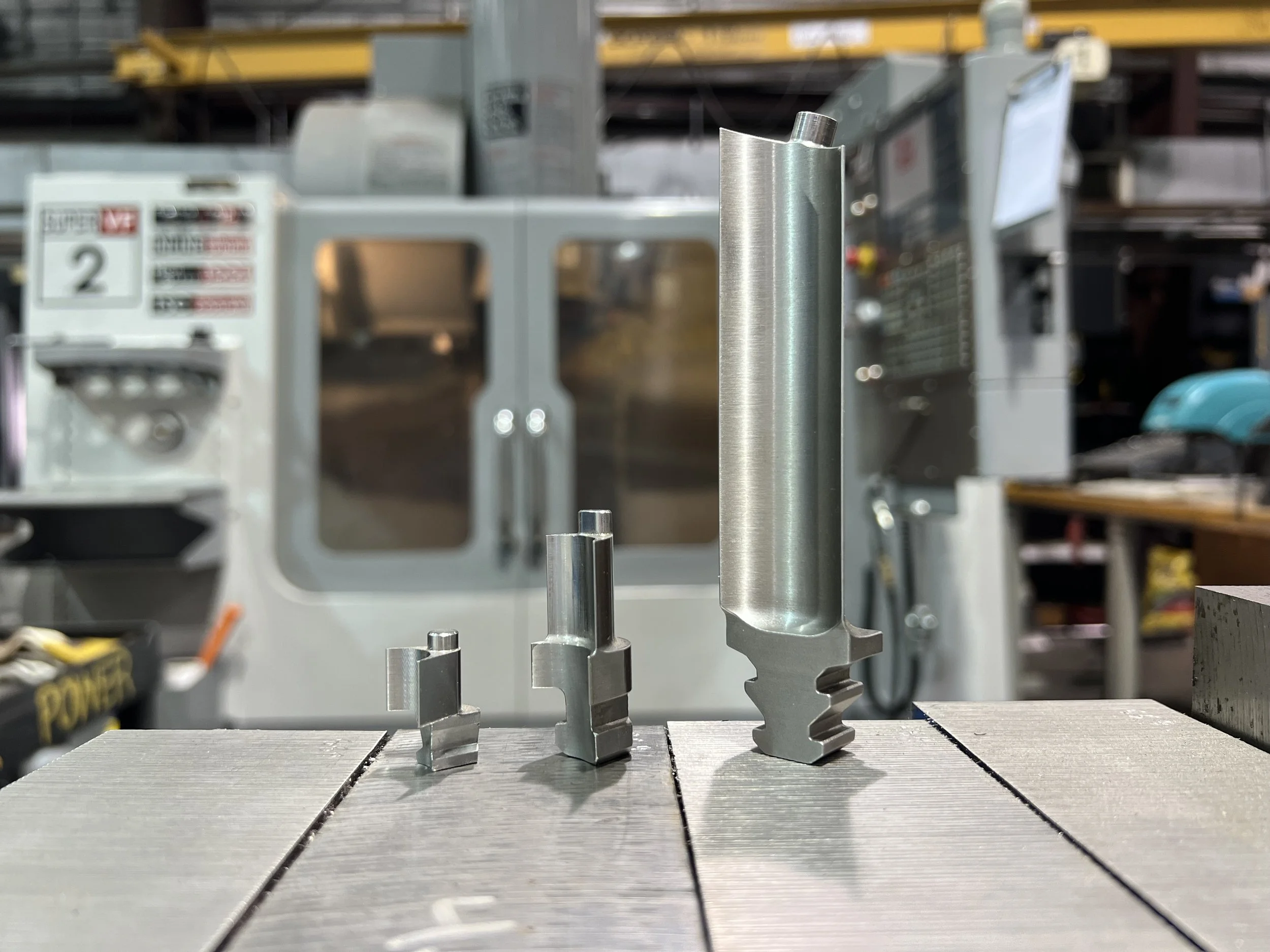

Steam Turbine Parts

Regardless of whether you need a total steam turbine overhaul or simply one part addressed, we provide custom designed parts for various types of steam turbines. The precisely fabricated steam turbine parts we employ solve the issues at hand and help promote and extend the service life of your steam turbine power system.